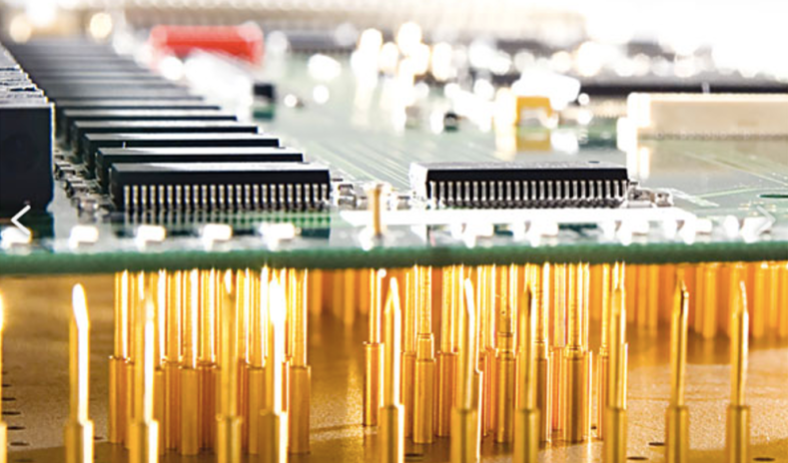

A bed of nails test fixture is a type of printed circuit board (PCB) testing jig equipped with an array of spring-loaded “nails” to establish electrical connections during quality control functional testing. These fixtures enable engineers to quickly validate assembled PCBs for manufacturing defects and verify proper performance before shipment.

A bed of nails tester is an electronic test fixture used to test Unit Under Test (UUT) and printed circuit boards (PCBs). It consists of numerous spring-loaded pogo pins inserted into a G-10 laminated sheet and aligned with tooling pins. These pogo pins make contact with test points on the PCB and connect to a measuring unit via wires. Pressing the device under test (DUT) against the bed ensures quick, reliable contact with multiple test points simultaneously.

Keypoints to note:

- Detects errors such as opens and shorts

- Verifies circuit logic functionality

- Crucial tool for PCB quality control

Manufacturing and programming such fixtures typically take four to six weeks. Mirotech manufactures bed of nails test fixtures in the Greater Toronto Area, providing high-quality solutions for efficient and accurate PCB testing.

Bed of Nail Test Fixtures and Their Uses

End-of-Line Quality Testing

Critical for end-of-line quality control in PCB assembly lines to catch errors before shipping products to clients.

Design Verification

Provides rapid connectivity during PCB prototyping and design verification to ensure circuit integrity, functionality, and performance meet specifications.

Troubleshooting

Aids engineers in diagnosing problems with faulty boards pulled from production or returned from field failures by investigating the root causes of bugs.

Focused Functional Test

Often used in tandem with flying probe testers to access targeted test nodes for extensive PCB testing needs.

Typical Bed of Nails Configurations for PCB Testing

Bed of Nails Fixture Designs

Utilize a wide array of spring-loaded pins to contact test points on PCBs. Beyond the basic pogo pin bed, several tester designs are tailored to specific application needs:

Standard Grid Array

The most common design, housing pogo pins in a regular grid array of rows and columns in a plate, suitable for many boards.

Custom Layouts

Tailored nail placements for odd board shapes and sizes or tricky access points, optimizing test coverage by matching PCB test pad locations.

Clamshell Fixtures

Utilize hinged top and bottom pogo pin jig plates that close over boards like a clamping cradle, allowing access to both sides of the boards.

Flying Probe Hybrids

Integrate movable flying probes on x-y axes to reach difficult test nodes that would be impractical to access with fixed nail positions.

Minimal Fixtures

For simple boards, “micro” bed of nail fixtures with small matrices of pogo pins reduce setup costs when only a few nodes require validation.

Your UUT is in safe hands, mechanically

The non-wiping mechanism involves a controlled, uniform, and consistent vertical movement during PCB testing. This ensures that all test points on the PCB are contacted simultaneously and with equal force by the test probes or pogo pins. This uniform contact is critical for the following reasons:

Consistent Test Results: By ensuring that each test point receives the same amount of pressure, the non-wiping mechanism contributes to the accuracy and repeatability of test results. This is crucial for identifying faults and verifying the functionality of the UUT.

Minimizing Wear and Tear: A key feature of the non-wiping action is that the test probes make contact with the test points without sliding across them. This reduces wear and tear on both the probes and the PCB, minimizing the risk of damage. As a result, the lifespan of the test fixture and the UUT is extended, reducing the frequency of replacements and repairs.

Enhanced Reliability: The linear collapse design, which incorporates the non-wiping mechanism, ensures precise alignment and reliable connections during testing. This mechanism maintains the integrity of the contact points, contributing to the overall reliability of the testing process.

Protection of Test Components: By avoiding lateral movement or sliding, the non-wiping mechanism protects sensitive components on the PCB. This is particularly important for high-density boards where test points are closely spaced, and any sliding action could cause shorts or other damage.

In summary, the non-wiping mechanism in UUT test fixture design is essential for maintaining the reliability, precision, and efficiency of the testing process. It ensures high-quality results while protecting both the test fixture and the unit under test, ultimately contributing to more robust and reliable electronic products. Whether using a bed of nails or flying probe testing, the principles of controlled, precise contact are critical for achieving accurate and repeatable test results.

Let’s work together on your

next project

We have been providing our customers with test fixtures for over 20 years. We have a proven track record of providing excellent customer service, quality products, and reasonable prices.